What is a hydraulic accumulator

Water container containing a membrane and designed to adjust the pressure /in the system is called a hydraulic accumulator. The elastic membrane is fixed on the metal housing of the accumulator using the flange and makes up a single structure with the body. In order to mount the battery to the overall structure, the flange is equipped with a threaded connection. The cavity between the elastic membrane and the case is filled with air under pressure. Air pressure is regulated in accordance with technical documents for the product. The membrane is made of high -quality synthetic rubber, does not contain poisonous substances, does not cause allergies. Designed for a large number of cycles and is able to withstand temperatures from -50, to +130 degrees. In the case of a sudden disconnection of electricity, the accumulating tank gives the supply of water to the system. The industry is made by hydraulic accumulators of various containers, from 1 liter to capacities for hundreds of liters.

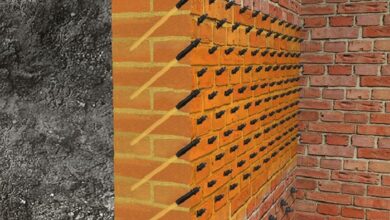

Mounted in the system, a pressure tank protects the system from a sharp increase in pressure (hydraulic boom), accumulation of water supply and protects the structure from too frequent inclusion cycles.

When falling in the pressure system, the relay is triggered and the pump is pumped into the system water until the relay is already working, only to high pressure. When the tap is opened, the water pressure drops and the cycle is repeated again.

If necessary, buying a hydraulic accumulator is easy, the main thing is to know the necessary parameters of the product. It is easy to guess that the volume of the accumulative tank often depends on the size of the room where it is used, and, accordingly, the volume of the hydraulic system. The smaller the volume of the system, the lower the recommended battery volume.

Pressure tanks of both horizontal and vertical performance are produced.

It should be noted that the installation of the hydroxide does not need permits. It is enough to contact a company specializing in the installation of such equipment. Moreover, the volume of work should include the commissioning.

Install the equipment in such a way as to get rid of vibration as much as possible. For this, during installation, special, rubber gaskets that compensate for vibration are used.

It is recommended to carry out the maintenance of the accumulator at least one once every six months and first of all check the air pressure.